Grain bins are essential constructions in agricultural operations, playing a important part in the storage and preservation of harvested grains. These cylindrical or rectangular storage units are meant to defend grain from environmental factors including humidity, pests, and temperature fluctuations, ensuring the quality of the stored product or service more than extended intervals. Farmers and grain handlers use these bins to protected their harvests, particularly in regions where climatic conditions can compromise the integrity of crops. Correct storage approaches and procedures are paramount to reaching optimum benefits, and being familiar with the intricacies of grain bins is key to efficient agricultural management.

When contemplating the benefits of employing grain bins, among the list of foremost components is their potential to keep up grain excellent. The composition of the grain bin, combined with its ventilation methods, ensures that grains remain dry and totally free from spoilage. Dampness is an important danger to stored grains, because it can lead to mould advancement, spoilage, and diminished nutritional worth. With correct aeration systems set up, grain bins can lessen humidity amounts, enabling air to flow into successfully and trying to keep the stored solutions in exceptional situation. This approach is not simply useful but also Charge-successful for extensive-phrase storage.

A standard false impression is that every one grain bins serve the exact same goal, Nonetheless they are available in several kinds and models, Each and every customized to specific demands. For example, some bins are Outfitted with drying devices that allow to the removing of excessive moisture from grains right away just after harvest. These drying bins are especially worthwhile for farmers in locations with significant humidity degrees or through damp harvest seasons. Then again, some grain bins are built exclusively for storage, focusing on preserving reliable disorders with no have to have For added drying mechanisms. Selecting the right kind of bin calls for thorough thought with the weather, crop variety, and storage length.

Temperature management is yet another crucial aspect of grain bin operation. Abnormal heat can injury grains, creating discoloration and decreasing their sector worth. Modern day grain bins are frequently equipped with temperature checking techniques, which offer serious-time facts to operators. By detecting temperature fluctuations, these programs permit for well timed interventions, for example adjusting air flow or turning the stored grain to distribute warmth evenly. This proactive method minimizes the potential risk of spoilage and makes sure that grains remain in primary condition until eventually They may be bought or utilised.

Grain bins also offer defense against pests, which could trigger major damage to stored solutions. Rodents, insects, along with other pests are drawn to grains because of their nutritional content. With no adequate storage remedies, infestations can manifest, resulting in considerable losses. Grain bins are built with pest-resistant components and so are designed to be sealed tightly, avoiding entry. Some devices even include integrated pest Handle actions, for example fumigation ports, that allow for for the applying of remedies without having opening the bin. This amount of defense is priceless for preserving the quality and quantity of stored grain.

The location and set up of the grain bin are very important factors in its effectiveness. Positioning a grain bin on elevated floor may also help reduce h2o from pooling all over its foundation for the duration of weighty rainfall. Moreover, the inspiration has to be powerful sufficient to support the burden with the bin and its contents. Suitable web site preparation, together with leveling and compacting the bottom, guarantees the stability with the construction. Farmers and operators should also consider accessibility, making sure that tools like conveyors and augers can competently load and unload grain.

Keeping a grain bin entails frequent inspections and maintenance. Over time, don and tear can compromise the integrity from the composition, leading to probable storage problems. Examining for leaks, cracks, and rust is essential to avoid moisture ingress and manage the bin's structural integrity. Cleaning the interior of your bin ahead of Every use is Similarly important, as residues from preceding harvests can attract pests or contaminate new grain. Adopting a regimen servicing schedule can extend the lifespan on the bin and optimize its performance.

Automation has revolutionized the way grain bins are managed, supplying advantage and precision. Automatic units can Management aeration, watch humidity ranges, and monitor inventory, cutting down the necessity for manual intervention. These technologies enrich the general efficiency of grain storage and provide operators with useful knowledge to enhance their procedures. Nevertheless, the Original investment decision in automation techniques can be superior, so farmers need to weigh the advantages against the costs to find out whether or not this strategy aligns with their desires.

Basic safety concerns must never ever be forgotten when working with grain bins. Mishaps can occur if right protocols are usually not followed, specifically throughout loading and unloading functions. Grain bins can become harmful when grain commences flowing, creating a quicksand-like effect that can lure people. Installing basic safety tools, such as harness devices and guardrails, is crucial to mitigate these threats. Moreover, supplying teaching for workers makes sure that they know how to operate the devices safely and react correctly in emergencies.

Vitality performance is really grain silo construction a rising issue in agricultural methods, and grain bins aren't any exception. Using energy-productive lovers and aeration systems can minimize electric power use whilst preserving best storage disorders. Farmers are more and more adopting sustainable methods, for example working with renewable energy resources to power grain bins, to minimize their environmental footprint. These developments not just contribute to environmental preservation but additionally reduced operational fees Eventually.

Innovations in grain bin technological innovation keep on to emerge, addressing difficulties faced by farmers and grain handlers. For instance, advancements in sensor technology allow For additional correct monitoring of grain disorders, furnishing specific insights into temperature, dampness, and pest activity. These sensors is often integrated into cell apps, providing operators distant entry to important details. This standard of connectivity enhances decision-building and allows for well timed interventions, ensuring that saved grain remains in top rated problem.

Grain bins play a pivotal position in the global foodstuff supply chain, guaranteeing that harvested crops are available for intake calendar year-round. By giving secure storage alternatives, these structures support stabilize market charges and reduce put up-harvest losses. This steadiness is particularly crucial for locations that rely on agriculture being a Most important source of revenue and food items security. Successful grain storage lets farmers to plan their product sales strategically, Making the most of sector fluctuations to maximize earnings.

The design and capability of a grain bin depend upon several things, such as the variety of grain being stored and also the anticipated duration of storage. Bigger bins are sometimes utilized for commodities for example corn, wheat, and soybeans, which might be generated in significant volumes. Scaled-down bins may very well be additional suited to area of interest crops or for farmers with constrained storage wants. Customizing a grain bin to meet specific requirements makes certain that it serves its function properly, minimizing squander and optimizing storage effectiveness.

Among the difficulties associated with grain bins is definitely the likely for uneven distribution of grain in the course of loading. Uneven loads can make stress details that compromise the structural integrity on the bin. To address this challenge, operators use strategies such as Heart loading, which distributes grain evenly and helps prevent overloading on one particular side. This follow is especially crucial for larger bins, the place imbalances can lead to important damage.

Grain bin management can be an ongoing method that needs attention to depth and also a proactive method. By keeping educated about the most up-to-date technologies and greatest techniques, farmers and operators can improve their storage methods and defend their investments. Whether via program routine maintenance, the adoption of recent systems, or maybe the implementation of safety measures, the objective is to make certain saved grain stays in the absolute best affliction. This motivation to excellence is exactly what drives the continual evolution of grain storage alternatives, guaranteeing they meet up with the needs of contemporary agriculture.

In conclusion, grain bins are indispensable towards the agricultural business, supplying a trustworthy implies of storing harvested crops. Their capability to shield grain from environmental elements, pests, and temperature fluctuations tends to make them a cornerstone of effective farm administration. By knowledge the intricacies of grain bin operation and maintenance, farmers can improve their storage performance, lessen losses, and contribute to the steady foods supply chain. As technology advancements and sustainability gets a priority, grain bins will go on to evolve, giving progressive solutions to your problems of recent agriculture.

Jake Lloyd Then & Now!

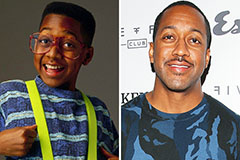

Jake Lloyd Then & Now! Jaleel White Then & Now!

Jaleel White Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now!